PP Polypropylene polymer

Price 76.0 INR/ Kilograms

PP Polypropylene polymer Specification

- Form

- Solid

- Usage & Applications

- Industrial

- Material

- PP

- Hardness

- Yes

- Grade

- injection moulding

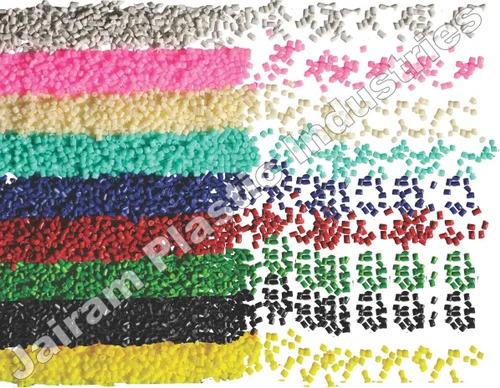

- Color

- Red, Orange, Pink, Blue, Black, Yellow, White.

- Warranty

- Yes

PP Polypropylene polymer Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 100000 Kilograms Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About PP Polypropylene polymer

PP colorred reprocess granules for molding & extrusion products.

we have wide range in color also we have inhouse pigmentation process so we can develop any color as per customers requirements.

we at JPI confident to supply high quaility PP / PPCP / HDPE reprocess granules that are suitable for injection molded and extrusion product since 1989.

monthly supply capacity 800MT reprocess granules.

our product widely use in all kind of injection molded products like household item, kitchenware products, plastic chair furniture, toys, air cooler, engineering molded products, automobile parts, telecommunication parts, hdpe pipe and fittings, pp box straps, hardware products, food container, glass, box etc. all kind of injection molded and extruded products.

Technical Specification

|

Packaging Type |

Bag |

|

Condition |

Atactic |

|

Packaging Size |

25 kg |

|

Application |

General Plastics |

|

Colour |

Pink, Purple, Green, Brown |

|

Types Of PP Granules |

Coloured, Natural, Milky |

Vivid & Versatile Color Range

Enhance your products with our PP Polypropylene polymers offered in seven distinct colors. The availability of Red, Orange, Pink, Blue, Black, Yellow, and White allows for design flexibility without compromising on performance. This makes our polymer suitable for branding purposes or color-coded industrial components.

Premium Quality Manufacturing

Our PP polymer is produced using advanced techniques tailored for injection moulding. This ensures a uniform solid form and dependable hardness, meeting stringent industrial standards. As a manufacturer and exporter based in India, we guarantee reliability and product quality with robust warranty coverage.

Diverse Industrial Applications

Engineered for industrial settings, our PP Polypropylene polymer supports a wide spectrum of usages, from automotive parts to consumer goods and packaging materials. Its solid form and material stability make it an optimal choice for businesses seeking durable solutions for large-scale or specialized applications.

FAQs of PP Polypropylene polymer:

Q: How is this PP Polypropylene polymer used in industrial applications?

A: This PP Polypropylene polymer is commonly used in industrial applications through injection moulding processes to create various components, such as automotive parts, containers, housings, and packaging materials, owing to its strength and durability.Q: What are the benefits of choosing this product for injection moulding?

A: The benefits include reliable consistency in solid form, vibrant color selection, high hardness, and compatibility with industrial standards. It also delivers cost-effectiveness and long-lasting performance, making it ideal for a wide range of moulded parts.Q: When should I consider using colored PP Polypropylene polymers?

A: Colored PP Polypropylene polymers are beneficial when color differentiation is needed for branding, safety, or functional identification in products. Use them for applications requiring color-coded components without the need for post-processing painting.Q: Where is this PP polymer manufactured and supplied?

A: This PP Polypropylene polymer is manufactured and supplied from India. As an exporter, manufacturer, supplier, and wholesaler, we cater to domestic as well as international industrial markets.Q: What process is recommended for shaping this polymer?

A: Injection moulding is the recommended process for shaping this grade of PP Polypropylene, as it allows for precision in complex geometries and high-volume production.Q: Does this product come with a warranty for industrial use?

A: Yes, we provide a warranty for this PP Polypropylene polymer, ensuring quality and performance for industrial applications. Details of the warranty can be provided upon request.Q: What makes this PP polymer suitable for industrial applications?

A: Its solid form, robust hardness, consistent quality, and broad color range make it exceptionally suitable for industrial use, offering durability, versatility, and ease of manufacturing for various industrial products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PP Granules Category

PP Black Granules

Price 56.0 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Form : Solid

Type : Other, PP Granules

Material : PP

Color : Black

Polypropylene Granules

Price 75.0 INR / Kilograms

Minimum Order Quantity : 1000 Bags

Form : Solid

Type : PP

Material : PP

Color : Red, Orange, Pink, Blue, Black, Yellow, White.

PP Grade Plastic Granules

Price 61 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Form : Granules

Type : Other, PP Grade Plastic Granules

Material : PP

Color : Multi Color

PP Molding Granules

Price 77 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Form : Granules

Type : Other, PP Molding Granules

Material : PP

Color : Multi Color

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS